Let’s discuss the question: how to temper a file knife. We summarize all relevant answers in section Q&A of website Abettes-culinary.com in category: MMO. See more related questions in the comments below.

Do you need to temper a knife made from a file?

If the blade is too hard/chippy, temper it again 50 degrees higher to bring the hardness down a bit more. If you temper too high to begin with (500F is pretty high for a simple steel) the steel will be softer than you want and you’ll have to anneal and re-HT it from scratch.

Do old files make good knives?

You can make a knife from anything that is hard enough to be sharp…. but the quality will vary. You can make a knife from things found in your garage, like old lawnmower blades, car springs, saw blades, and FILES. Of these , a file is probably the only one that will make a decent knife.

Bevels and Heat Treat On a Farrier’s Rasp Knife | Knife making | Daily Vlog

[su_youtube url=”https://www.youtube.com/watch?v=hA_dud0IqGc”]

Images related to the topicBevels and Heat Treat On a Farrier’s Rasp Knife | Knife making | Daily Vlog

Do you have to heat treat a rasp knife?

But you must be very careful not to burn the metal, if you do then you’ll have to heat treat it to regain the hardness, so when making this knife whenever it gets to hot to hold cool it in water.

Can you temper steel without oven?

Sand the metal shiny. Lay the steel in your coals spine down Start pumping some air to the coals the steel will start changing color as the temp raises in the metal.

Do I need to anneal my knife?

When you anneal a wood carving knife blank, annealing it makes the steel much softer to work with and makes it faster to grind and easier to bend as well as making it less springy when you attempt to bend it. Annealed steel will also bend with a smaller radius before cracking and failing.

What is the difference between normalizing and tempering?

Tempering treatment means that the steel after quenching hardening or normalization treatment is cooled down at a certain rate after being immersed for a period of time below the critical temperature.

What does normalizing a knife do?

Maybe someone can explain it better, but from what I understand normalizing re-crystalizes the steel from all the torcher you put it through during forging. It also helps to refine the grain structure makeing a stronger, tougher blade.

How do you temper steel?

tempering, in metallurgy, process of improving the characteristics of a metal, especially steel, by heating it to a high temperature, though below the melting point, then cooling it, usually in air. The process has the effect of toughening by lessening brittleness and reducing internal stresses.

Are files case hardened?

High quality files are commonly made of a hardenable steel like 1095 or W1. Cheap files can be made out of something considerably softer, and are often case-hardened.

Are Nicholson files case hardened?

They are very hard below the soft skin,but that leaves the teeth soft,too soft to file a saw made of 1095 steel,which even tried the durability of the old USA made Nicholsons. They might file lesser quality saws that are made of lower quality steel,or were hardened to a lower Rockwell number.

Are files high carbon steel?

The steel used for files is very high in carbon content, as it makes up 1.35-1.4% of its composition. 1.5% is normally the maximum for carbon steels.

How To Heat Treat A Knife | The 4 Steps You NEED To Know

[su_youtube url=”https://www.youtube.com/watch?v=5HCVPg4MXOU”]

Images related to the topicHow To Heat Treat A Knife | The 4 Steps You NEED To Know

What steel are hoof rasps made of?

Bellota Files and Rasps are made of High Carbon Steel with added Chrome contents. The combination of high Carbon and Chrome alloy enables the steel to behave optimally and uniformly in its hardening heat treatment and to configure files with very high levels of hardness and wear resistance.

What are Farrier rasps made of?

Rasp are a crap shoot. Many are case hardened steel meaning that it was made from a steel that has a low carbon content (wont harden) and is heated and carbon introduced creating an hard eggshell.

What is brine quenching?

Brine quenching, or salt bath quenching, has the fastest cooling rate. Brine is a solution of water and salt. Salts have been used in the quenching process for many of years. They have a wide operating temperature range, and can minimize problems involving iron and steel parts.

Can you quench W1 steel in oil?

Quenching: This material may be water quenched, but brine quenching is preferred. Water or brine quench to 150 to 200° F. Oil quenching is sometimes used for light sections and where maximum hardness is not required.

How do you temper steel at home?

- Prepare the tools for the process. …

- Use a forge or small ceramic oven if possible. …

- Put on heavy gloves and safety glasses before heating the steel. …

- Immerse the metal into the oil when it glows a deep red. …

- Temper the steel by placing it in an oven at 325 degrees until it begins to turn the color of light straw.

How many times should you normalize a knife?

Heat the blade evenly and touch it to a magnet to test its temperature. Steel becomes non-magnetic at critical temperatures, so torch it, test it against the magnet, and let it cool to room temperature three times to normalize it.

Can you heat treat after annealing?

Hot working or cold working after the annealing process alters the metal structure, so further heat treatments may be used to achieve the properties required. With knowledge of the composition and phase diagram, heat treatment can be used to adjust from harder and more brittle to softer and more ductile.

How can I anneal steel at home?

So how do you anneal steel? To anneal steel, heat it up about 100 degrees F above its critical temperature, soak it at that temp for 1 hour per inch of thickness, and let it cool at a maximum rate of 70 F per hour. Ok, that’s the short answer.

Why tempering is required after quenching?

After being quenched, the metal is in a very hard state, but it’s brittle. The steel is tempered to reduce some of the hardness and increase ductility. It’s heated for a set period of time at a temperature that falls between 400° F and 1,105° F.

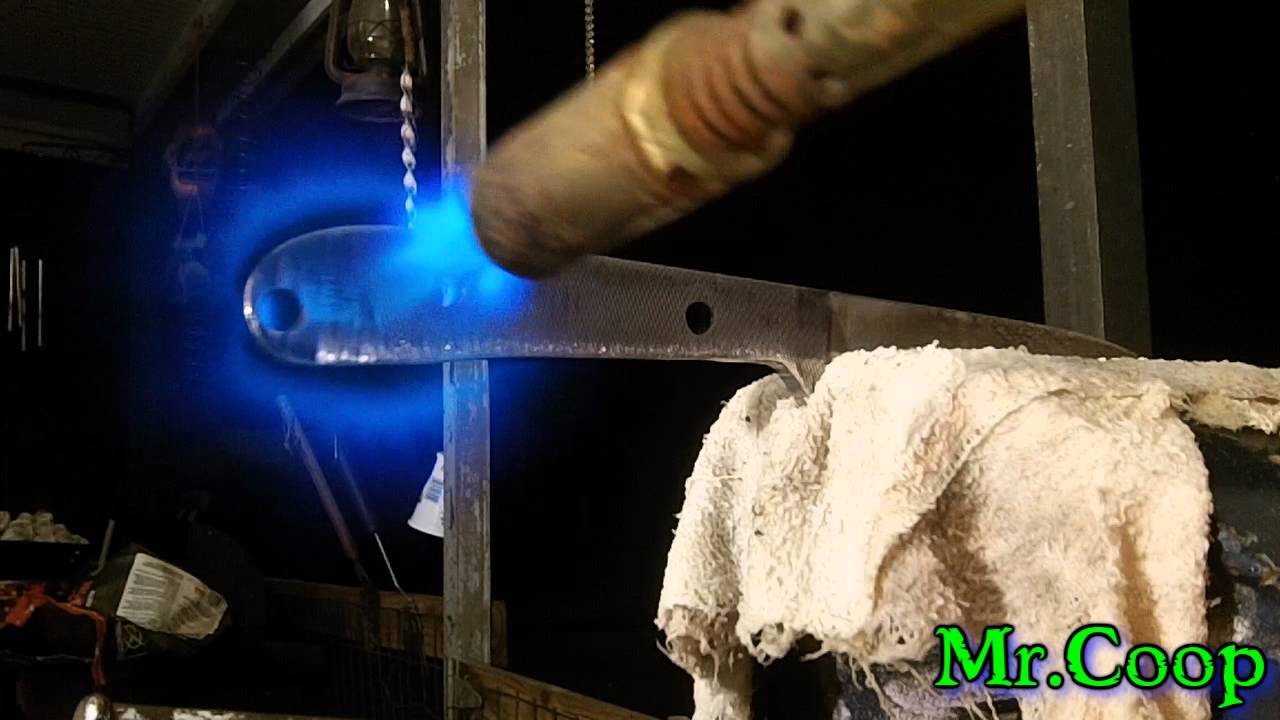

Tempering File Knife With Torch .

[su_youtube url=”https://www.youtube.com/watch?v=r7TwkJ5Jp78″]

Images related to the topicTempering File Knife With Torch .

What is quench annealing?

The high-temperature tempering and quenching treatment results in a tempered sorbate structure. After annealing, the grains are refined. the structure is adjusted, and the tissue defects are eliminated. Quenching causes the supercooled austenite to undergo martensite or bainite transformation.

Is annealing the same as quench?

The main purpose of annealing is to remove the hardness of metal alloys and increase ductility. After quenching, metal tends to become brittle, and that can increase the risk of breakage. Annealing balances the properties of metal alloys to maximize strength and durability for a variety of applications.

Related searches

- how to anneal a file

- how to take the temper out of a file

- how to quench a file knife

- how to make a bushcraft knife from a file

- how to make a knife from a file step by step

- how to temper a knife with a torch

- annealing a file with a torch

- how to temper knives

- annealing file knife

- how to anneal a knife blade

- make a knife from a file without forging

- how to soften a file to make a knife

- do you need to temper a knife

- making a knife from a file

- how long should you temper a knife

Information related to the topic how to temper a file knife

Here are the search results of the thread how to temper a file knife from Bing. You can read more if you want.

You have just come across an article on the topic how to temper a file knife. If you found this article useful, please share it. Thank you very much.